● online

- Compatible Arduino Pro Mini 5V 16Mhz - Atmega328 -

- Breadboard 400 titik lubang Bread board Projectboa

- LCD 16x2 / 1602 Display Biru + I2C Backpack Sudah

- PWM DC 10A Motor 12V-40V Pulse Width Modulation Sp

- Arduino Nano V3 Atmega328P CH340G 5V 16Mhz

- Motor servo MG996R TowerPro Metal Gear

- Raspberry Pi 4 Model B 4GB Original UK E14 Raspi 4

- Raspberry Pi 4 Model B - 2GB RAM Raspberry Pi 4B

- Selamat Datang di Indomaker ❯ Silahkan pesan produk sesuai kebutuhan anda, kami siap melayani.

- Selamat Datang di Indomaker ❯ Silahkan pesan produk sesuai kebutuhan anda, kami siap melayani.

How to Calibrate Your CNC Machine

- Run a GRBL streamer software. You can use Grbl Control, GRBL Controller, Candle, UltimateCNC, or others. Even you can use Hyper Terminal or Putty at this step, but it’s not recommended if you are not mastering GRBL command (note: in this article I use UtimateCNC, you can download it here freely)

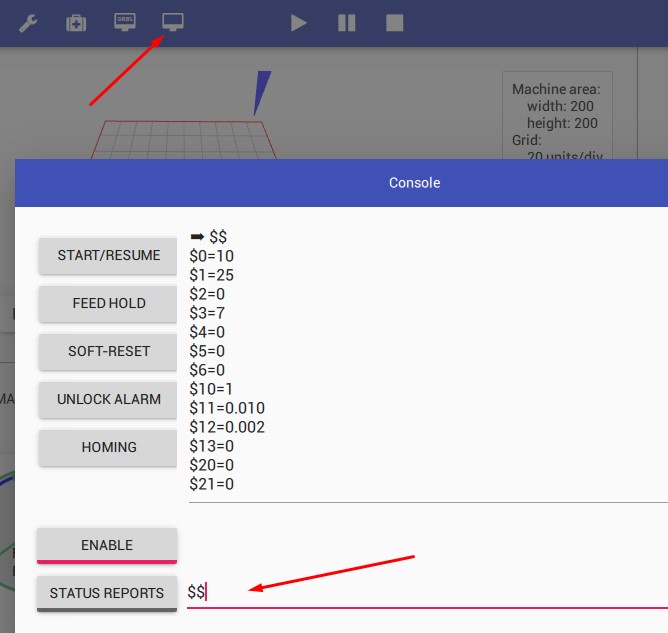

- Check your GRBL initial configuration by typing the’ $$’ command in the console. Look at the result shown on your display

-

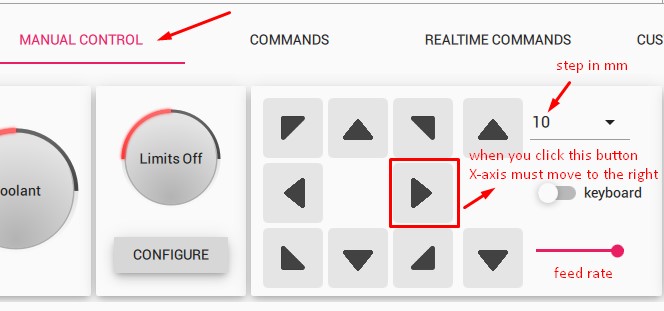

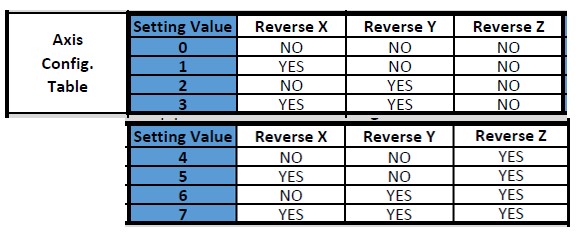

- Set Axis direction. At this step, you can set axis direction depends on your hardware (stepper motor) set up. Try these configurations, until you got correct direction regarding the navigation button in GRBL software. See picture below

enter one of above configuration using command $3=value in the console (ex: $3=6)

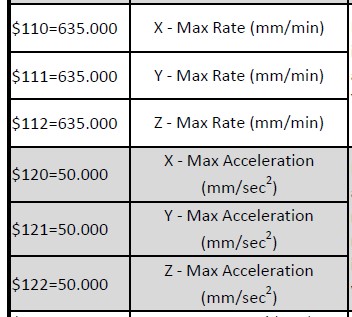

enter one of above configuration using command $3=value in the console (ex: $3=6) - Set speed of the stepper motor. You can do this step by entering the command below for each axis in Console

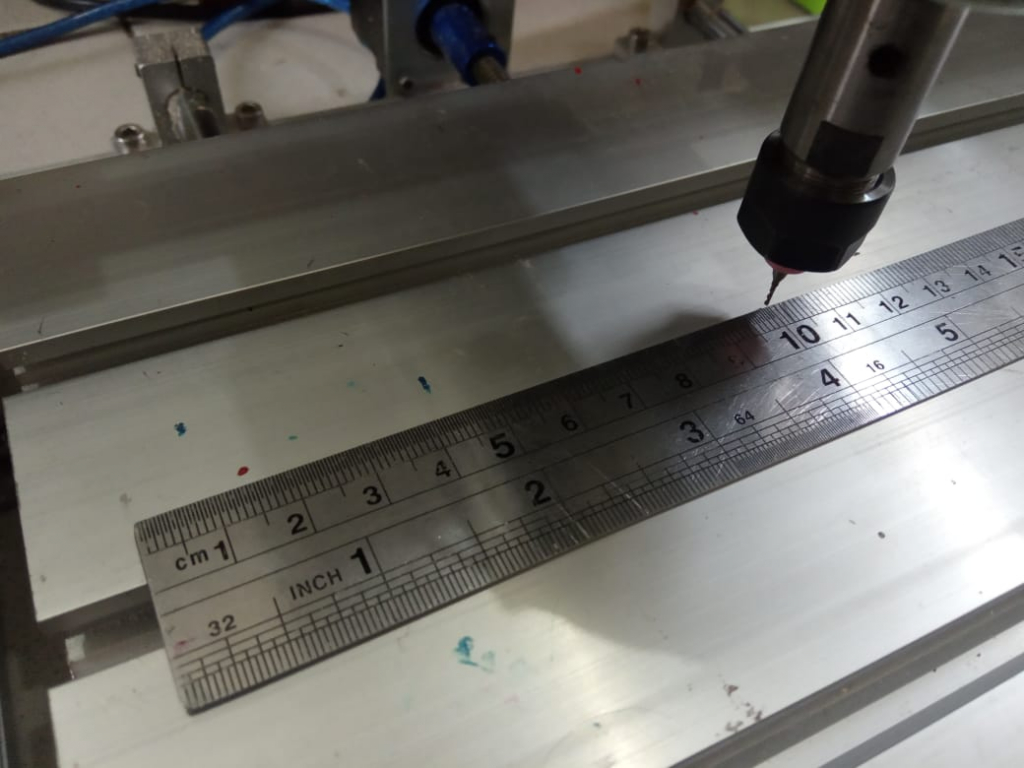

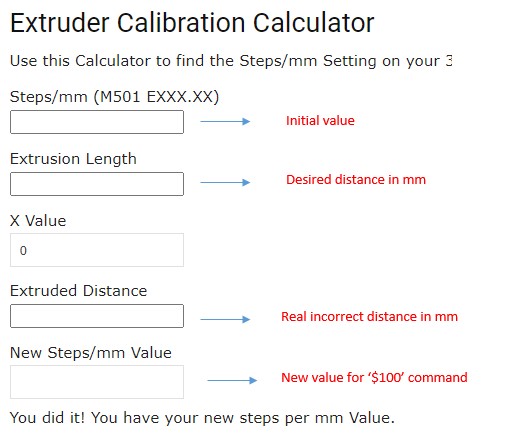

- Distance calibration. This point is the main calibration step, so please be careful to run this step or your CNC will less precisely moving or move incorrectly at all.

How to Calibrate Your CNC Machine

Melanjutkan tutorial dari postingan sebelumnya tentang cara memulai menggunakan telegram pada NodeMCU, kali kita akan membahas cara membuat notifikasinya... selengkapnya

Apa itu relay? Relay merupakan sebuah saklar yang dikendalikan dengan aliran arus listrik. Pada relay terdapat 2 bagian utama... selengkapnya

Tutorial kali ini akan membahas mengenai penggunaan sensor IR (infrared) untuk mengontrol AC / pendingin udara menggunakan jaringan... selengkapnya

Oke kali ini akan membahas seputar sensor fingerprint, dimana fungsi dari fingerprint ini adalah sebagai validasi data identitas dengan... selengkapnya

Pada beberapa profesi yang menggunakan bantuan suatu aplikasi ataupun perangkat lunak sangatlah banyak. Nyatanya dengan adanya berbagai macam perangkat... selengkapnya

Alat dan Bahan ESP8266 Lolin(Wemos) NodeMcu v3 beli Modul MAX7219 LED dot matrix 8×8 beli Jenis Modul Modul MAX7219... selengkapnya

Push Button dan LED (Light Emitting Diode) menjadi sebuah komponen yang umum ditemukan pada piranti elektronik sehingga menjadikan... selengkapnya

RTC DS3231 merupakan sebuah jenis modul yang dapat menghasilkan waktu digital secara realtime dengan tambahan sebuah baterai tipe kancing... selengkapnya

Melihat potensi dari android itu sendiri, akhirnya banyak orang yang berlomba lomba belajar memperdalam sistem operasi ini. Tentunya akan... selengkapnya

LDR (Light Dependent Resistor) adalah sensor cahaya yang berbasis nilai resistansi. Semakin banyak intensitas cahaya yang diterima maka semakin... selengkapnya

Spesifikasi: 20mm Kapton Tape Polymide Film Gold High Temp isolasi Tahan Panas Harga Tertera: 1 Roll Kapton Tape Polymide Film… selengkapnya

Rp 219.000Tang Crimping Press Skun Ratchet YTH SN-48B Model YTH SN-48B FOR NON INSULATED TERMINAL YTH SN-48B dengan mata Press 0.5… selengkapnya

Rp 150.000ESP-WROOM-32 is Powered by Espressif’s most advanced SoC, the ESP-WROOM-32 features high performance, a wide range of peripherals, Wi-Fi and… selengkapnya

Rp 38.400Kabel jumper Dupont untuk jumper Arduino atau Raspberry Pi 20 cm Male to Male 1 lembar = 40 kabel

Rp 11.300ASIS adalah perangkat Smart Soket listrik produk dari Indomaker.com. Nama ‘ASIS’ merupakan kependekan dari ‘Andika Smart IoT Socket’. Secara umum,… selengkapnya

Rp 120.000Features – Calibrated directly in Celsius (Centigrade) – Linear + 10.0 mV/C scale factor – 0.5C accuracy guaranteeable (at +25C)… selengkapnya

Rp 8.000Spesifikasi: 1. 14 digital input / output ports RX, TX, D2 ~ D13, 2. 8 analog input ports A0 ~… selengkapnya

Rp 82.500Paket B: + 1 pcs ESP32 D1 Mini + 4 pcs 10p Male Header + 4 pcs 10p Female Header… selengkapnya

Rp 91.000TILT SENSOR adalah sensor untuk mendeteksi sudut kemiringan / derajat, dimana cara kerja sensor ini adalah dengan menggunakan 2 buah… selengkapnya

Rp 9.800Kabel Jumper Dupont Pelangi 10 cm.. male to female 1 lembar isi 40 kabel

Rp 9.000

Saat ini belum tersedia komentar.